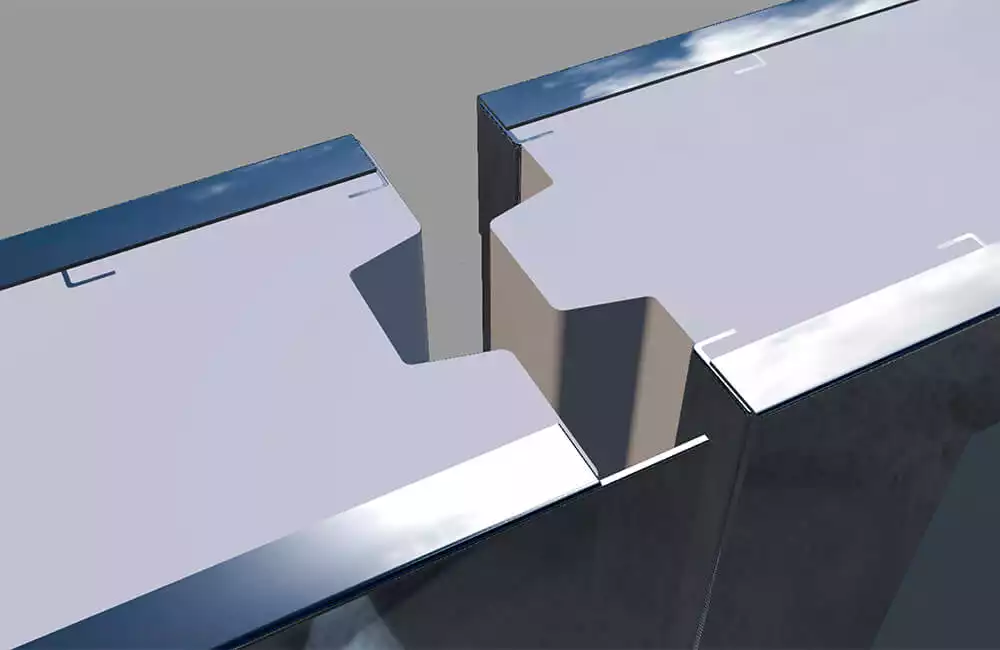

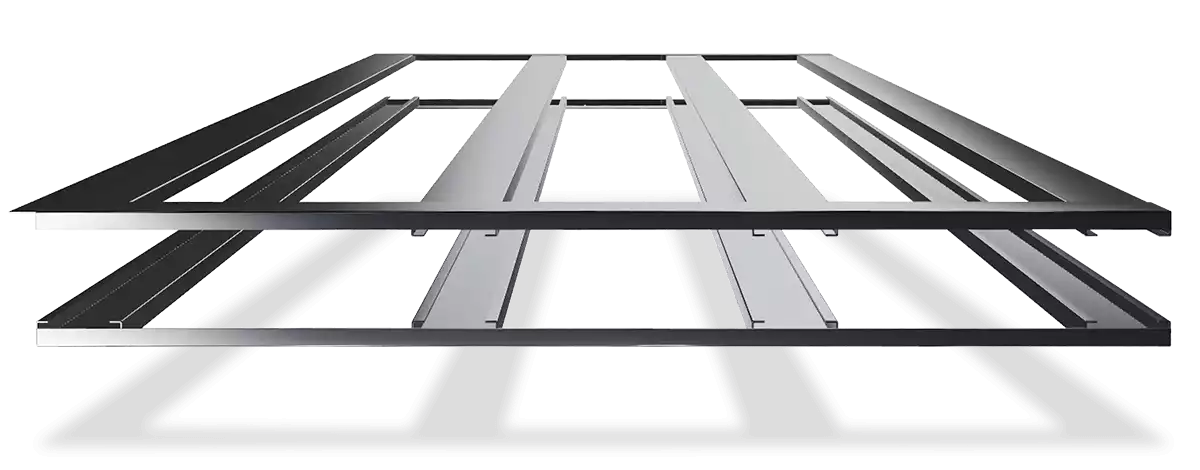

ThermaSteel’s technology eliminates thermal bridging and with 58% increased air tightness, raises effective thermal performance (R Rt U values are significantly higher complying with ASHRAE 90.1 and with the 2021 energy codes for all zones. Learn more about our Composite Structural Insulated Panels). See thermal performance in summary table

While appliances, electrical, and mechanical systems of a building have a short life expectancy and require replacing every 5-15 years, the building envelope is the one item of the building that is expected to perform for the entire life of the building. At the same time – it is the most expensive and the hardest to replace. Using the right system for the building is a major decision of the designer. The collective impact of thermal bridging, air leak reduction, humidity abatement, and thermal value has a major impact on the energy performance of the building envelope. Today, common practice to sizing mechanical equipment is based on effective thermal performance of R14.

However, comparing such performance to ThermaSteel’s effective R28 to R61 allows you to:

- Downsize mechanical equipment by 50% and in some cases, more

- Reduce or even eliminate ducts

- When eliminating ducts, ceiling can be dropped by 12″ per floor height, reducing building height – reducing the construction cost

- Smaller units mean lower energy bills, and less costly maintenance

These advantages reduce initial construction costs and long-term energy bills by 2/3 and lower maintenance costs of the system. While this amount may look insignificant on a single-family house, when adding the units needed for a hotel or an assisted living facility this translates to 2-5% Return over investment [ROI]. When ducts are downsized or eliminated the ceiling can drop down up to 12″ inches per every floor level. Adding the total area (sqf) of building envelope times the cost to build it, savings multiply when building with ThermaSteel panels.

Closed Cell Technology

While some building projects use open-cell materials, our closed-cell technology eliminates moisture absorption, increases structural strength, reduces air infiltration, lowers perm rate, and reduces sound transfer. All performing better than most SIP and to open-cell methods. In particular, when temperature declines, open cell materials contract, meaning their energy efficiency is negatively impacted. With our closed-cell technology, thermal performance is immune to temperature cycles, allowing ThermaSteel to maintain effective R-Values for its entire lifetime: Roughly 400 years! ThermaSteel uses M77B EPS type which does not ignite [see EPS fire test]. Every bag of raw materials arrives with a UL certification [see the EPS bags]. In addition, closed-cell technology is a stronger structure making it a good application for impact absorption, seismic design, hurricane, and ballistic applications. And of course our low perm ratio, even when exposed in the ground.

- Low perm

- Constant thermal performance (no thermal drifting)

- Strong and stable

- Continuous support for the sheathing

- Higher STC acoustic performance